ESS Shaft seal for 3/4" to 3-3/4" shafts

The mechanical shaft seal is the most modern and frequently installed seal in the construction of ships: from small boats to serious warships. It is also easy to install when retrofitting a vessel in place of a stuffing box seal.

More info

Mechanical seals have become widespread due to a host of positive properties: they do not require maintenance during normal operation, operate with little leakage (or without leakage as such), and are characterized by long service life, including under severe conditions of pressure, temperature and aggressive environments. Also, the seal is insensitive to the radial displacement of the shaft relative to the housing in comparison with an stuffing box or lip seal. Protects the shaft because it does not touch its surface.

Any vessel can easily be retrofitted with a shaft seal; Available for shaft diameters from ¾” to 6-1/2” (19 to 165 mm). The average service life of our seals is 8 years.

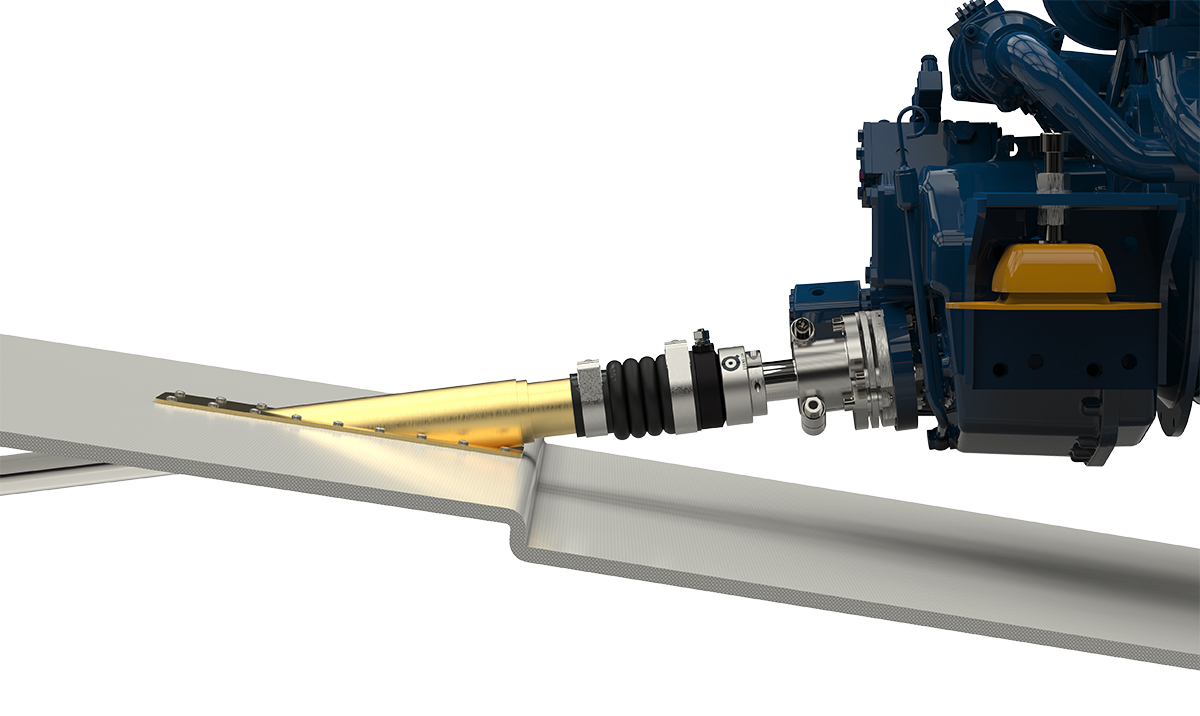

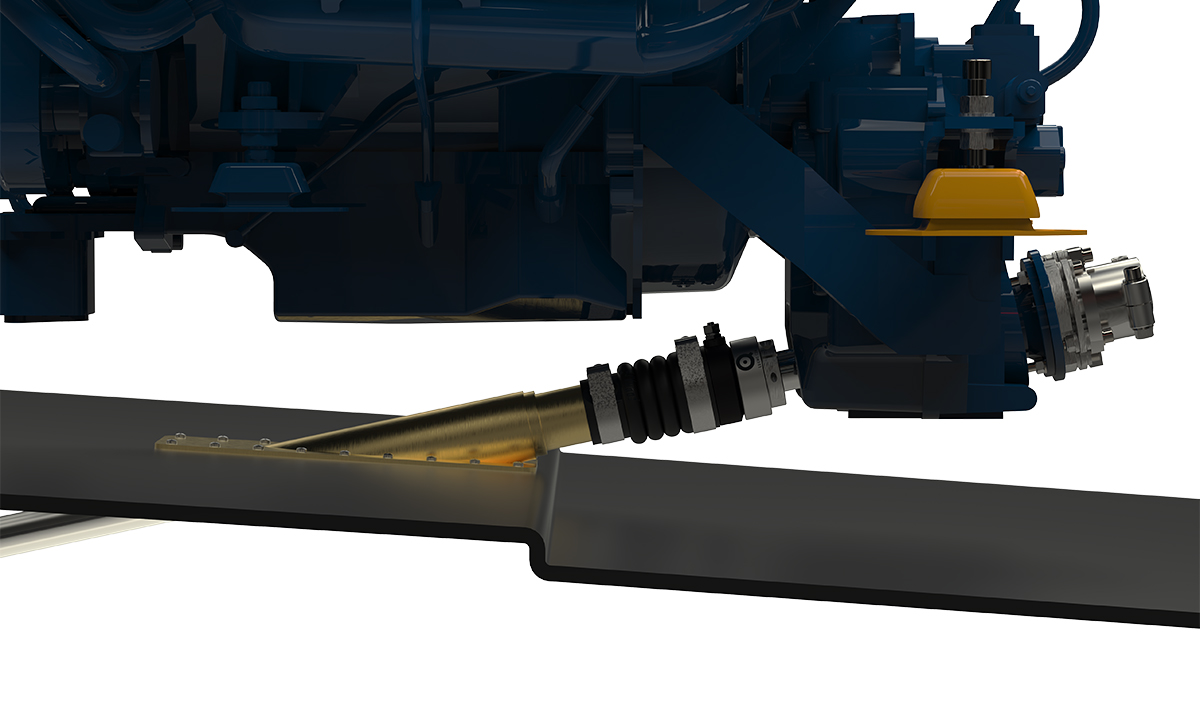

The seal can be installed on any shaft, regardless of transmission design - Vee Drive or direct.

FACE SEAL, WHAT IS IT?

The main element of the seal is the friction pair of the rotor and stator, made in the form of rings located coaxially and perpendicular to the axis of rotation of the shaft. One of the rings - the rotor is fixed to the shaft and rotates with it. Secondly, the stator is motionless and pressed against the rotor. Tightness is ensured by contact pressure in the plane of contact of the rotor and stator. The rings are made of special, hard, wear-resistant materials with high thermal conductivity and low friction coefficient. The wear of the friction pair is small (0.02 mm over 850-1000 hours of operation).

How It Works

The silicone bellows (5) is installed on the stern tube of the vessel. It is secured with a clamp (6). Next, a stainless rotor (1) is installed on the shaft, with which it is necessary to compress the bellows (5) by 15-25 mm. Secure the rotor (1) to the shaft with set screws. Next, if necessary, install the retaining ring (0) and tighten it with screws. All is ready.

-

An additional retaining ring to hold the shaft in case of emergency seal failure or additional retention of the rotor on the shaft.

-

Stainless steel rotor. It is secured to the propeller shaft using set screws. Inside contains 2 rubber rings for tightness.

-

High density carbon stator with special impregnation, manufactured under high pressure and temperature.

-

Forced water supply to cool and lubricate the seal during operation. Connects to the general cooling system.

-

Clamp for fastening the stator (2) with bellows (5)

-

A bellows made of high-temperature and durable silicone with internal layers of reinforcing fabric serves to seal the connection and ensure contact pressure between the rotor (1) and the stator (2).

-

Clamp for attaching the seal to the stern tube.

Comparison of nitrile rubber and silicone

Compared to other elastomers, nitrile rubber (NBR) is characterized by higher hardness and abrasion resistance, but when the temperature rises above +80C it hardens, becomes brittle, and its aging process is significantly accelerated . Moreover, products made from nitrile demonstrate low resistance to atmospheric factors: weather conditions, ozone.

Silicone is based on high molecular weight organic silicon compounds. The differences between silicone rubber and regular rubber are due to its chemical composition. The base of silicones contains alternating oxygen and silicon atoms, and the base of conventional rubber brands contains hydrogen atoms.

The significantly higher energy potential of oxygen-silicon bonds is the main reason for the unique physical and chemical properties of silicones. So, we are talking about:

- weather resistance;

- resistance to most chemical compounds;

- heat resistance;

- electrical insulating properties - in this parameter, silicone is ahead of all other rubbers;

- pronounced anti-adhesive properties;

- physiological safety.

The combination of so many excellent technical and operational characteristics allows the use of silicone products in many industries, an incomplete list of which is presented: rocket and aircraft manufacturing; machine-, instrument-, machine-tool-, shipbuilding; food industry; production of medical equipment; carriage building; pharmaceutical and chemical industries.

| Material | Tensile strength, MPa | Elongation at break, % | Shore hardness, A | Tear resistance Kn/M | Operating temperature range, C | Pressure, MPa | Durability |

| Nitrile rubber | 9.8-10.8 | 130 | 60-80 | 20 | from -5 to +80 | 2.5 | unstable to: acetone; benzene; sulfur dioxide; hydrochloric and formic acids |

| Silicone | 11.6 | 439 | 72 | not less than 25.9 | from -50 to +230 | to 1 | ozone resistance |