Hemi Marine... and a little history

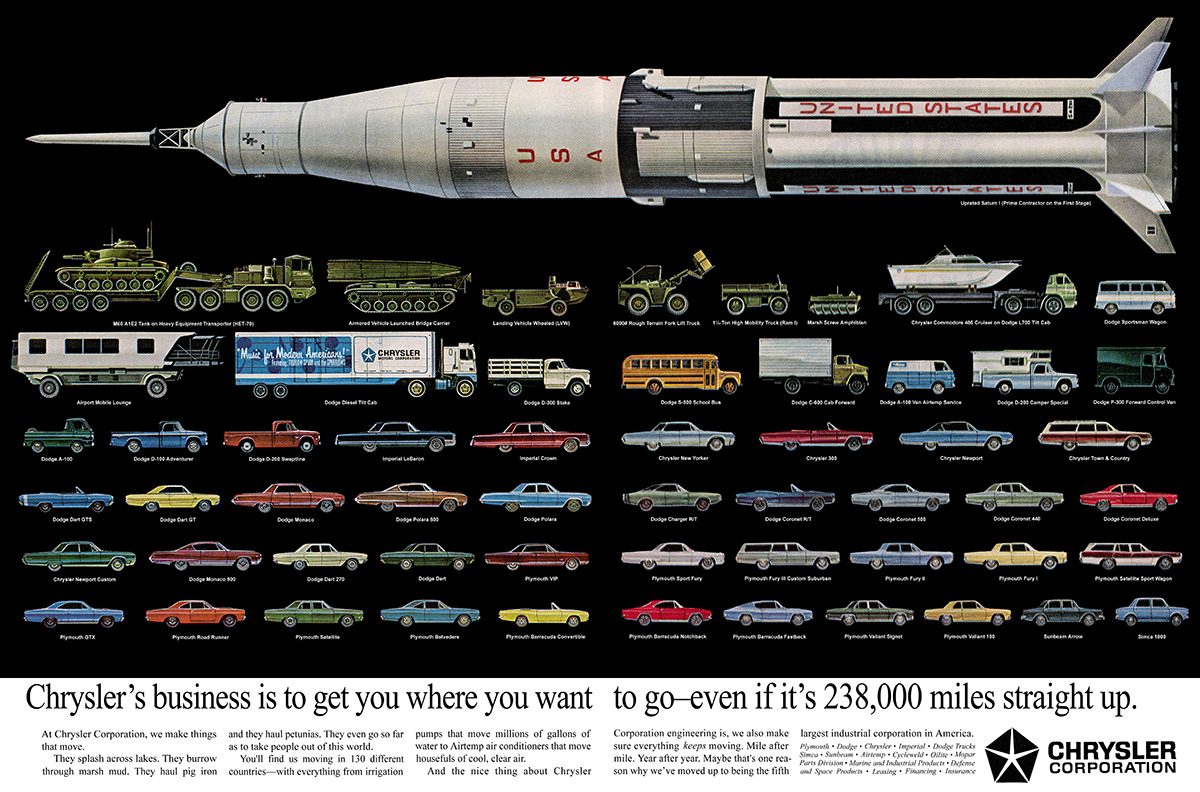

Most people know the Chrysler Corporation only for cars and car engines. Although her interests extended not only on land, but also in water... and even in space (Space Division Chrysler Corp.)

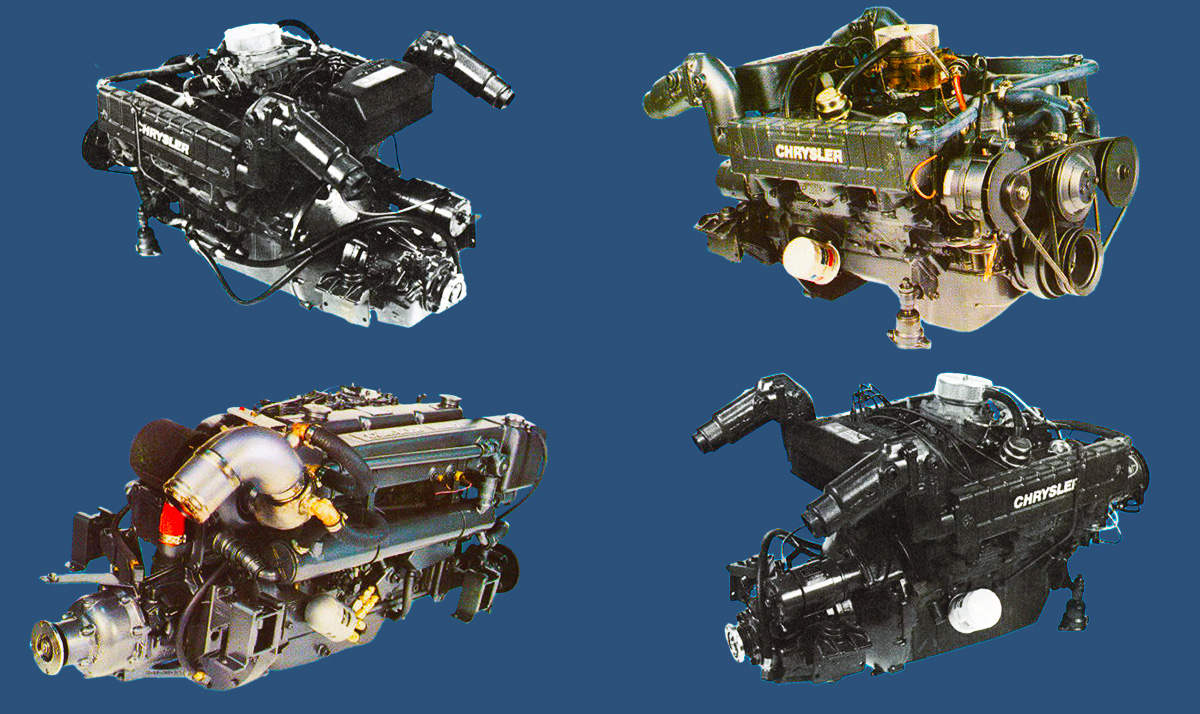

Chrysler Marine has specialized in the production of marine engines since the 1920s. They are prized for their reliability, durability and performance, making them a popular choice for recreational and commercial boats.

Chrysler Marine offered a wide range of marine engines from outboard to inboard models of various sizes. The range of V8 models was from 270 to 440 cid. Of course, there were HEMIs in this range.

There is no Chrysler Marine in the modern world. GM has taken over the entire market. And the industry is looking at electric motors and batteries. I wanted to build an American powerful gasoline marine engine with charisma and, of course, a beautiful exhaust sound. The choice fell on my beloved Gen III HEMI... and turning it into a marine version of the engine.

This project is primarily a tribute to the engineering staff and history. The idea to create a marine version of the engine appeared in 2017 and was gradually implemented. All requests to Chrysler (FCA) to obtain specifications, dimensions, drawings or fragments thereof remained unanswered. I had to figure it all out myself.

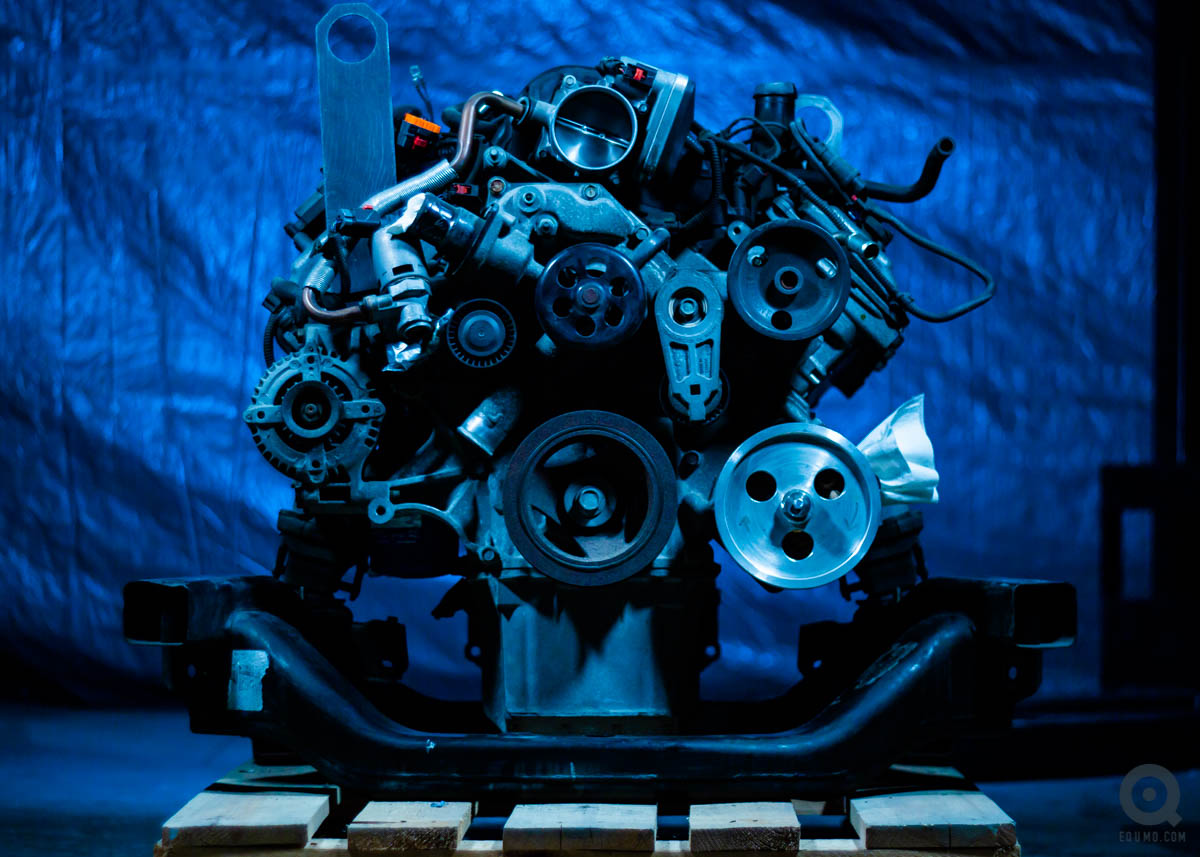

So, my HemiMarine engine assembly has the following characteristics:

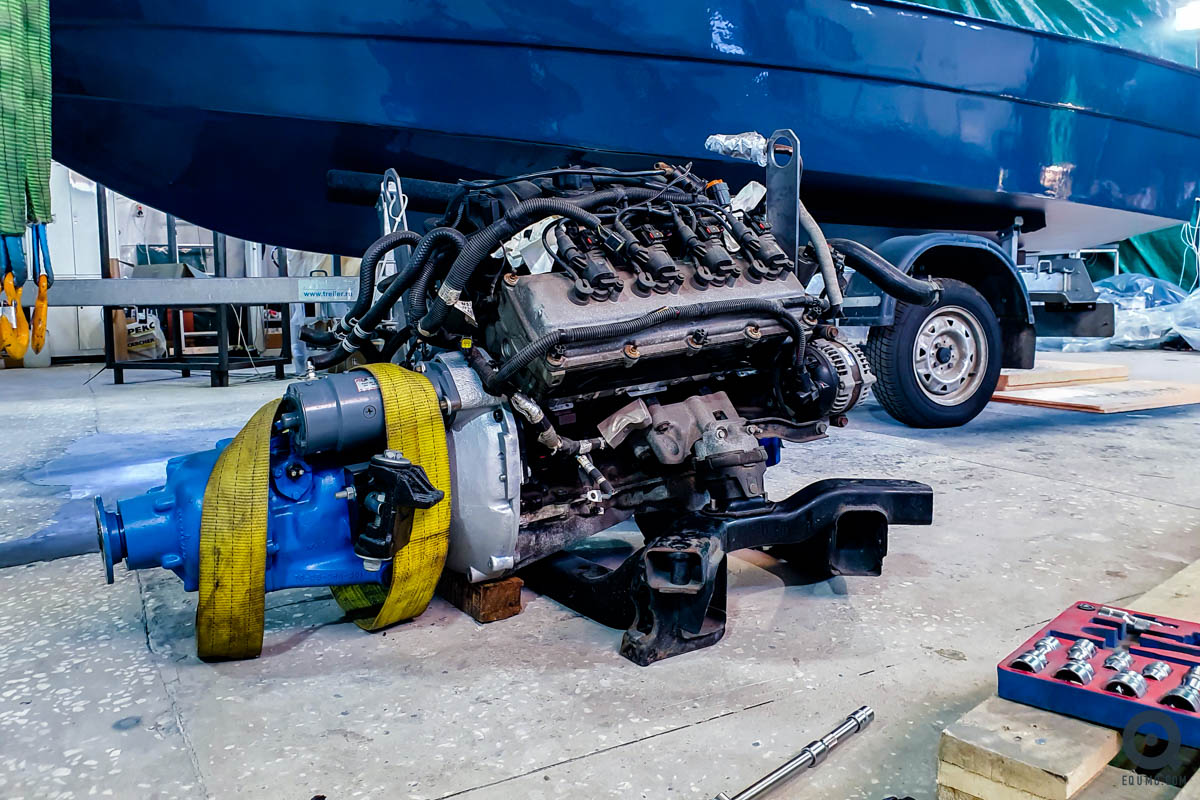

The Hemi Marine powerplant was assembled in my Equmo workshop and is a 345 cid (5.7L) Hemi Gen III engine, producing about 380 hp . and a torque of 388 lb-ft (526Nm) to the reverse gearbox.

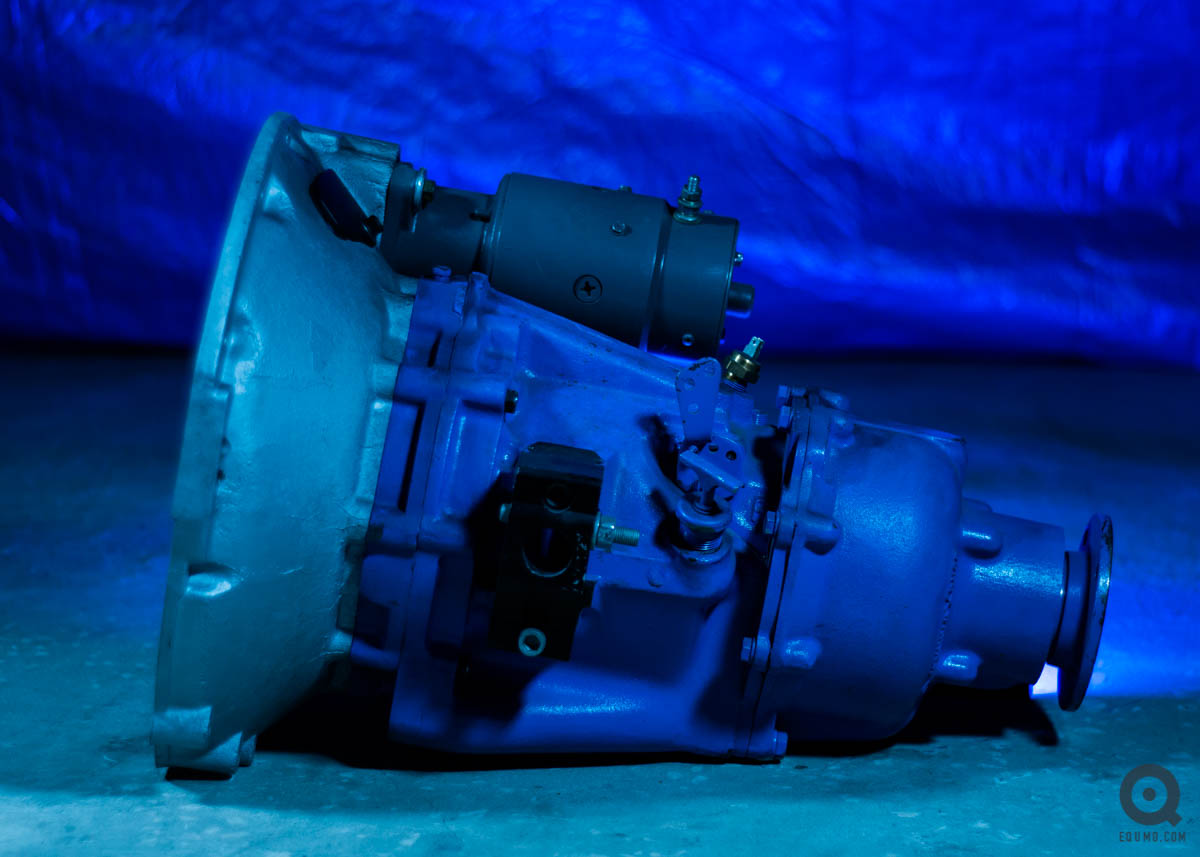

The engine is coupled with Velvet Drive transmission with aspect ratio 1.52. Which gives 590 Lb-Ft (800Nm) torque at the shaft output at a shaft speed of 2900 rpm.

For this job I had to design and manufacture an engine flywheel, a pressure washer and adapt a damper to it.

Designed and manufactured from high-strength quality steel forgings. After processing, it was subjected to galvanic cadmium plating to protect it from the environment.

Washers for pressing the flywheel to the crankshaft. Designed and manufactured from hardened steel. Cadmium-plated.

The damper was adapted to the engine flywheel and VelvetDrive Transmission. Cadmium coating.

Also, the engine control unit was reprogrammed to work as part of the power plant.

This propulsion system is part of the Vee Drive drive when remanufacturing a sports boat. This is discussed in more detail in the next article. .link.

If you want to repeat this power plant or part of it, you can chat. I am also considering cooperation on other engines and interesting types of work.